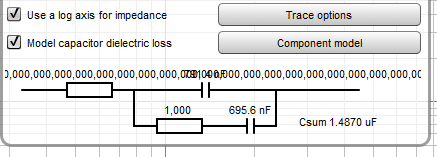

John, thanks so much for changing the displayed values to 4 digits - very impressive. I have had a little time to make a batch of capacitor impedance measurements - very repeatable values when the cursor selected frequency is in the goldilocks range (not too low, not too high). On one measurement I noted that one value in the component model window has a bug - attached file - and overlays another component value - perhaps due to the model complexity used. All other measurements have been fine and shown a simple R-C model.

For the polystyrene dielectric capacitors I have been measuring, using a cursor selected frequency and the cap value in the bottom left appears to be valid, whereas the model component value of capacitance shows some minor difference that I can't seem to align with any spot value in the 100Hz to 20kHz range.

I've tried twice to load the mdat (60Meg) but it doesn't seem to show in post one it reaches 100% upload (?)

For the polystyrene dielectric capacitors I have been measuring, using a cursor selected frequency and the cap value in the bottom left appears to be valid, whereas the model component value of capacitance shows some minor difference that I can't seem to align with any spot value in the 100Hz to 20kHz range.

I've tried twice to load the mdat (60Meg) but it doesn't seem to show in post one it reaches 100% upload (?)

Last edited:

Here is what it should look like, fixed for the next build:

Here is what it should look like, fixed for the next build: