ddude003

AV Addict

More

- Preamp, Processor or Receiver

- PrimaLuna Dialogue Premium TubePre (2 channel+sub)

- Main Amp

- McIntosh MC152 SS Amp (2 channel)

- Additional Amp

- Yamaha RX-A850 Pro (the other 5 channels lol)

- Computer Audio

- MacBook Pro, Custom i7 7700k De-lid 2xAsus1080ti GFX Audirvana Studio Hang Loose Convolver Tone Projects Michelangelo, Pulsar Massive & 8200, LiquidSonics, SoX

- DAC

- Chord Electronics Ltd. Qutest

- Universal / Blu-ray / CD Player

- Sony UBP-X700 /M Ultra HD 4K HDR & PS5

- Front Speakers

- Martin Logan ElectroMotion ESL

- Center Channel Speaker

- Martin Logan Motion C2

- Surround Speakers

- Martin Logan Motion 4

- Surround Back Speakers

- Martin Logan Motion 4 (yes, another set of these)

- Subwoofers

- Martin Logan Dynamo 700

- Other Speakers or Equipment

- Cifte 12AU7 NOS & Genalex Gold Lion Tubes in Pre

- Video Display Device

- Samsung The Premiere LSP7T UST Laser Projector

- Screen

- Elite Screens Aeon CLR3 0.8 Gain 103-inch

- Remote Control

- PrimaLuna, Lumin iApp, Samsung & Yamaha

- Streaming Equipment

- Netgear Nighthawk S8000 Streaming Switch, Lumin U1 Mini Streamer Transport

- Streaming Subscriptions

- QoBuz Studio Premier, Amazon Prime & Netflix

- Other Equipment

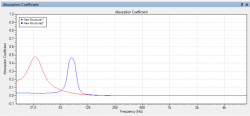

- ThrowRug, SaddleBlankets, WideBand & Bass Traps...

Thank you Adhock, suspended panel and limp mass absorbers is another fun area that will drive Horacio crazy... 8^) And the sound flow software looks interesting... Is that 30 day trial full functioning?