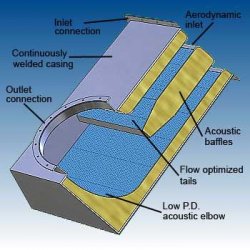

AN HVAC silencer is what you need Matt (right up my alley of expertise)

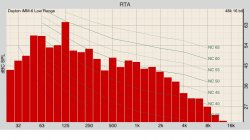

View attachment 8591

You will need to build a box with acoustic baffles in it

Hey Tony, that is essentially what I designed and built/had built, but it didn't work. I did have a professional company design a better one that was optimized for my specs, but the size and cost was too much. I had to reject the proposal and redesigned it to be smaller. It compromised the performance, in one area, by a lot.

I'll try to create a drawing of what I have.

On the supply side, there is a square trunk line that splits off the main, off of that is a 14" spiral round duct that then splits into 6" supplies to various places. Roughly 6 feet of that is lined with 1.5" fiberglass duct liner. A portion of the square duct is also lined. Another 4-5 feet of the round 14" duct is lined past where I tied in to help prevent sound from migrating into that room (that is the duct that feeds the livingroom above the theater). After the last tie in there is a large empty section of the 14" duct. I lined that and the end cap with 1.5" of fiberglass duct liner and then made wedges that were adhered in place. This creates a large absorbing chamber that technically acts as a helmhotlz resonator but of unuseful tuning. That is why I filled it so much with fiberglass.

At the point where I tied into the 14" duct, I used a 10" spiral duct using 1.5" of duct liner (so the inside is about 7" of free area) with a metal mesh liner around the fiberglass. That feeds into an expansion chamber that is about 20" wide, 14" deep, and 10" tall. It has a hard 90 degree bend for the air, and its lined with insulation as well. At the bottom of the chamber it shrinks to a 14x8 opening for the duct. I know that a linear duct would have been much better (and that was in the original proposal) but the cost was in the 1000's of dollars and required cutting the trusses above with notches or lowering the ceiling in that section. That made me nervous. The only other option for a linear duct was to have it run the long way, but again, really expensive.

In the original design, I had them install turning vanes for the expansion box with air flow optimized tails. Just like in your picture, but curves with the air (and with a solid center). When it was installed, air was VERY noisy. You could hear the flow as if it was a vacuum. I didn't know what the problem was, but we found that if you removed the expansion box, it went away. We had the turning vanes removed and the problem went away (but those also acted as sound baffles). I think that the expansion box needed to be much larger and I was told that turning vanes need to be fairly far from the outlet, mine was just 6" away or so.

On the return side things are better. A 14" spiral duct main return trunk is tapped immediately by a large 24" cube expansion chamber with turning vanes. Fully lined with 1.5" material, 3" thick in a few areas (doubled up). The shape is airflow optimized and it has entry and exit such that sound is a very indirect path. That ties into a 10" spiral duct material lined with 1.5" material for about 3 feet. That then feeds into what I call a muffler. The muffler is like a round version of what you showed. It expands to 14" again Iit's actually made of 14" special acoustically lined spiral duct from 18 gauge damped steel and a metal perf liner. There are two 1" thick baffles that run the length of this muffler with a mesh outer layer, fiberglass core, and steel air straightener in the middle. This whole thing is about 48" long. Attached to that is normal 10" spiral steel duct, acoustically damped metal, and 1.5" duct liner. That feeds into another expansion chamber like endbox with 14x8 opening. It is acoustically damped and lined. In the 10" duct there is a 24" long 8" piece of that special acoustic spiral duct with an end cap. Its front has a 6" opening with a 4" length. The acoustic size is 8"x24" body with a 6"x4" port. That comes in at around 120hz once volume loss from the damping and baffle is included and matched the drone at the outlet. It reduced the LF drone by about 10-12dB and made it inaudible in the room. It's highly audible in every other room in the house.

The Return has audible air noise at the outlet. Again, the better solution would have been either a linear duct or a much larger opening. I didn't have the budget for that. However, no noise transmits audibly through the return. It's the supply side where I took shortcuts. What I should have done is built a large 14" diameter silencer/muffler that runs parallel with the main trunk and taps in differently. The problem was just cost and placement. I didn't have room for that and let my HVAC guy talk me out of my plan. I could have built a bulkhead by the wall and it wouldn't have bothered anyone.

I have an after the fact plan, an external silencer that mounted to the 8x14 opening and is made of duct board and plywood. I just need time to construct and mount it. I suspect it will work quite well.